Product Description

Product Description

This series power tiller can be equipped with lamp, water pump, ridge, sprayer, trailer, furrow plough, seeder, fertilizer distributor. etc. Well perform between mountain and hilly farmland, dry and paddy field, orchard, vegetable greenhouse, potato land, corn land and CHINAMFG land, sand land etc.

Parameters of Power Tiller

| GASOLINE MODEL | |||

| Item | 170 | 177 | 190 |

| Engine | 7hp | 9hp | 12hp |

| Transmission type | Gear drive/belt drive | ||

| Start model | Manual/electric starter | ||

| Working width | 500mm | ≥960mm | 1050-1350mm |

| Working depth | ≥100mm | 200mm | 200mm |

| Size of wheel | 400-8/350-6 | ||

| Adjustment of handle bar | 360 degree horizon and 45 degree vertical | ||

| Fuel consumption | ≤10kh/ha | ||

| Fuel tank | 5L | ||

| Weight(KG) | 120 | 132 | 150 |

| Working efficiency | o.1-0.2acre/h | o.1-0.2acre/h | 0.3-0.4acre/h |

| Working speed | >0.3m/s | ||

| Package size | 79*45.5*86cm | 98*57*81cm | 98*57*81cm |

| DIESEL MODEL | |||

| Item | 173 | 178 | 186 |

| Engine | 7hp | 9hp | 12hp |

| Transmission type | Gear drive | ||

| Start model | Manual/electric starter | ||

| Working width | 500mm | ≥960mm | 1050-1350mm |

| Working depth | ≥100mm | 200mm | 200mm |

| Size of wheel | 400-8/350-6 | ||

| Adjustment of handle bar | 360 degree horizon and 45 degree vertical | ||

| Fuel consumption | ≤10kh/ha | ||

| Fuel tank | 5L | ||

| Weight(KG) | 164kg | 178kg | 182kg |

| Working efficiency | o.1-0.2acre/h | o.1-0.2acre/h | 0.3-0.4acre/h |

| Working speed | >0.3m/s | ||

| Package size | 79*45.5*86cm | 102*57*81cm | 102*57*81cm |

1.7hp vertical type gasoline engine is little to control.

2.Better small machine could be guarantee the farm worker in some time.

3.Its advantage is fit for old man,woman to finish tilling fields.

4.Special diesel engine must need special transmission to match each other.so the gearbox of tiller is our patent solely.

5.Two wheels tractors be supplied from 4.85KW ( 6hp) to 14.70kw (20hp)

6.Features: Compact,Agile,Light,Reliable,Convenience,High Quality.

7.Suitable for paddy fields,upland plains,mountain and hilly areas.and for plough,rotary tillage,sow,threshing ,suction and so on.

8.Equipped with lightnings for driving at night.

9.Can be used as a stationary power source for drainage and irrigation.

10.With quick coupling,easy to change farming implements. Cultivator,mower,trailer,water pump,power tiller,snow blower,rotary plough,etc.

11. Different product colors is optional, to adapt to different market

Packaging & Shipping

After Sales Service

FAQ

1.Q:Are you a factory or trading company?

A:Yes, we are a factory, and our factory is located in ZheJiang China. Nearly HangZhou port.

2.Q:How about the quality control in your factory?

A:Full as people are always paying great attention to the quality controlling from the beginning to the end. With more than 10 years experience in this file, each product will be tested 1 by 1 before packing, our product has passed CE GS etc.

3. Q: Is it all right to make customer’s own brand name?

A:Yes,we can accept OEM, also can add your logo on it.

4. Q:What is the payment term you can accept?

A:Usually we can accept T/T,western union and other payment term by negotiation.

5. Q:Can I get 1 sample?

A:Sure you can,and you need to pay for sample charge which will be returned after the mass order signed.

Contact

| After-sales Service: | Video Technical Support, Online Support, No Overse |

|---|---|

| Type: | Rotary Tiller |

| Application Field: | Agriculture |

| Farming Policy: | Bed Planting Machinery |

| Power Source: | Diesel |

| Operation: | Soil Preparation Machinery, Fixed Operation |

| Samples: |

US$ 205/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

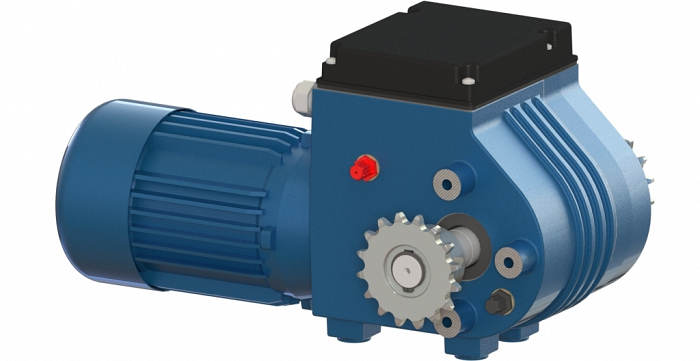

Factors to Consider When Selecting a Greenhouse Gearbox

Choosing the right greenhouse gearbox for your setup is crucial to ensure optimal performance and functionality. Here are the key factors to consider:

- Load Capacity: Evaluate the weight and resistance of the louvers or other components the gearbox will control. Ensure the gearbox can handle the load without straining or wearing out.

- Gearbox Ratio: Select a gearbox with the appropriate ratio to achieve the desired louver movement based on the motor’s input. The ratio determines how much the louver will open or close per motor rotation.

- Speed Requirements: Consider the speed at which you need the ventilation louvers to open or close. Choose a gearbox that can provide the necessary speed while maintaining precision.

- Automation Compatibility: Determine whether the gearbox can be easily integrated into your greenhouse’s automation system. Compatibility with sensors, controllers, and other automation components is essential for efficient operation.

- Accuracy and Precision: Look for a gearbox that offers accurate and precise position control. This ensures that the louvers can be adjusted to the exact desired position for optimal ventilation control.

- Environmental Conditions: Consider the environmental conditions within the greenhouse, including temperature and humidity. Choose a gearbox that can withstand these conditions without compromising performance or durability.

- Installation and Maintenance: Evaluate the ease of installation and maintenance of the gearbox. Access for maintenance and the availability of replacement parts are important considerations.

- Customization: Determine if the gearbox can be customized to suit the specific layout and requirements of your greenhouse. Customization options allow for a tailored solution that fits your needs.

- Budget: Compare the cost of the gearbox with its features and capabilities. Choose a gearbox that provides the best value for your budget while meeting your requirements.

By carefully considering these factors, you can select the right greenhouse gearbox that will enhance the efficiency and effectiveness of your greenhouse ventilation and shading systems.

Examples of Greenhouses Using Gearbox Technology

Various greenhouses around the world have embraced gearbox technology to enhance their operations and achieve better energy efficiency:

- Almeria Greenhouses, Spain: Almeria is known for its vast network of high-tech greenhouses that use advanced gearbox-controlled ventilation and shading systems. These systems ensure optimal growing conditions while conserving energy.

- Netherlands Greenhouses: The Netherlands is a pioneer in greenhouse technology. Many Dutch greenhouses utilize gearbox-driven systems for ventilation, temperature control, and shading. These systems enable year-round cultivation and reduce energy consumption.

- Gotham Greens, USA: This urban greenhouse company uses gearbox technology to control automated systems that adjust lighting, temperature, and irrigation. The precise control offered by gearboxes helps optimize plant growth and minimize resource usage.

- Tomita Farm, Japan: Located in Tokyo, this technologically advanced greenhouse utilizes gearboxes to regulate ventilation, cooling, and heating systems. The gearboxes enable the greenhouse to maintain stable conditions in the face of changing external temperatures.

- Emirates Hydroponics Farms, UAE: In the arid desert environment of the UAE, greenhouses rely on gearbox-controlled irrigation systems to provide water-efficient cultivation. Gearboxes play a crucial role in managing water distribution and usage.

These examples showcase how greenhouse gearbox technology is used globally to optimize growing environments, conserve resources, and contribute to sustainable agricultural practices.

Industries Utilizing Greenhouse Gearboxes for Controlled Environments

Greenhouse gearboxes find extensive applications in various industries that require controlled environments for optimal plant growth and productivity:

- Agriculture and Horticulture: Greenhouses are commonly used for cultivating crops, flowers, and ornamental plants. Gearboxes are essential for automating ventilation, shading, and irrigation systems, enabling precise control over growing conditions.

- Research and Experimentation: Research institutions and educational facilities utilize greenhouses to study plant physiology, genetics, and growth under specific conditions. Gearboxes assist in creating controlled environments for conducting experiments and analyzing plant responses.

- Food Production: The agriculture industry employs greenhouses to grow vegetables, herbs, and fruits year-round. Gearboxes help optimize temperature, humidity, and light levels, contributing to higher yields and faster growth rates.

- Floriculture: Greenhouses are crucial for producing flowers and floral arrangements. Gearboxes enable automated processes that ensure consistent quality and aesthetics in floral products.

- Nurseries: Plant nurseries use greenhouses to propagate and grow young plants before transplanting them to outdoor settings. Gearboxes aid in maintaining ideal conditions for the healthy development of seedlings.

- Pharmaceuticals: Pharmaceutical companies may use controlled environments to cultivate medicinal plants for research and production. Gearboxes assist in creating the necessary conditions for optimal plant growth and active compound development.

Overall, greenhouse gearboxes play a pivotal role in supporting industries that rely on controlled environments to achieve specific plant-related goals and outcomes.

editor by CX 2023-09-13