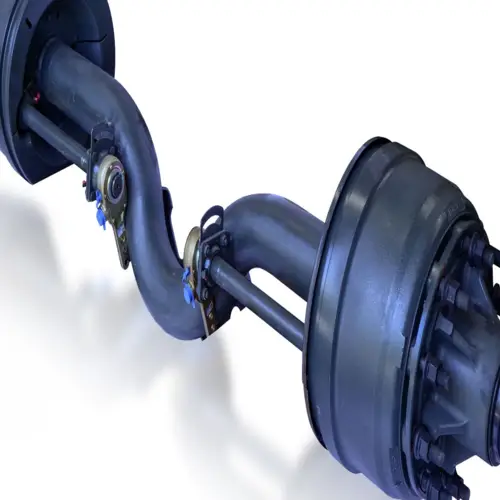

China Hot Selling Trailer Hub Kit for 2000 lbs Axle

The China Hot Selling Trailer Hub Kit for 2000 lbs Axle is a high-quality trailer accessory designed for durability and performance. This kit includes a 4 to 4 bolt idler hub and a 1 round BT8 spindle, making it suitable for 2000 lbs axle trailer axle hub wheel bearing kits with a 1-1/16 inch spindle.

Product Description

The Trailer Hub 4 Lug on 4 inch Spacing fits 2,000 lb. axles with 1-inch bearings. It features a 1 1/4″ diameter, 3 3/8″ long shaft, and a BT8 1″ spindle. The spindle comes with a spindle nut, spindle washer, and cotter pin for easy installation.

- 4-4″ BT8 hub pre-raced and studded

- Hub includes inner and outer bearing L44643, seal, grease cap, and lug nuts

- Rated at 1000 lbs. per spindle, 2 will hold 2,000 lbs.

| Part NO. | Capacity | Bolt Pattern | Outer Bearing | Inner Bearing |

| TH005 | 2000lbs | 4 on 4″ | 44643/10 | 44643/10 |

HangZhou CHINAMFG Machinery Co., Ltd is a professional manufacturer of trailer parts located in HangZhou, ZHangZhoug Province, China. With a focus on delivering high-quality products, we have been serving customers since 2016. Our wide range of trailer parts and accessories includes towbars, axles, brake drums, hubs, brake discs, bearings, springs, suspension kits, couplings, mudguards, U-bolts, jockey wheels, keel rollers and brackets, wobble rollers, wheel spacers, equalizers, and more.

If you have specific drawings or specifications for trailer parts, mechanical parts, or wheels, we can provide you with a customized price quote. Please feel free to contact us with any inquiries or requirements.

Frequently Asked Questions

-

Do you have a factory?

Yes, we have our own factory and a team of experienced engineers who can meet your unique requirements.

-

Can I have a sample order?

Yes, we welcome sample orders for testing and quality checking. Mixed samples are also acceptable.

-

Can I print my logo on your product?

Yes, we can accommodate your exact requirements, including printing your logo on our products.

-

How do you ship the goods and how long does it take to arrive?

We usually ship via DHL, UPS, or FedEx, with an estimated delivery time of 3-5 days. Airline and sea shipping options are also available.

-

What are your advantages?

With over 10 years of experience as a professional supplier, we prioritize quality and price. Our products are exported to various countries, and we have the expertise to address any challenges that may arise.

At HangZhou CHINAMFG Machinery Co., Ltd, we offer OEM services, allowing you to use your own brand or ours. Our professional team can assist you in designing the packaging. We pride ourselves on providing excellent customer service, ensuring that your inquiries are promptly answered. We also prioritize the protection of your sales area, design ideas, and private information.

When you visit our company, we will provide transportation and assist in hotel bookings. If you’re interested in exploring local scenic spots, our colleagues will be happy to accompany you. We offer a warranty for our products, and our after-sales service includes timely updates on production and delivery, as well as addressing any design or quality concerns you may have.

For more information about our products and services, please feel free to contact us. We look forward to assisting you with your industrial needs.

Performance Characteristics of Axle Hub

Axle hub is an essential component of the wheel assembly of a vehicle and has several performance characteristics. Firstly, it is responsible for holding the wheel bearing together and ensuring that it spins smoothly. Secondly, the axle hub helps in the smooth transfer of torque from the axle shaft to the wheel. Thirdly, it plays a crucial role in supporting the weight of the vehicle, thus providing stability and balance. Fourthly, it helps in reducing the heat generated due to friction, thereby preventing the brake system from overheating and ensuring proper functioning.

Types and Characteristics of Axle Hub

There are two main types of axle hubs: front and rear. Front axle hubs are located at the front wheels, while the rear axle hubs are located at the rear wheels. Axle hubs can also be classified based on their material composition, such as cast iron, steel, and aluminum. Cast iron axle hubs are durable and can withstand high loads, while steel and aluminum axle hubs are lightweight and provide better fuel efficiency. Moreover, axle hubs can be either shielded or sealed, depending on their intended use.

Advantages of Axle Hub made of Different Materials

Axle hubs made of cast iron have excellent strength and durability, making them suitable for heavy-duty applications. Steel axle hubs are lightweight and offer better fuel efficiency and are ideal for light-duty applications. Aluminum axle hubs are corrosion-resistant, lightweight, and offer excellent heat dissipation, making them suitable for racing cars. Additionally, aluminum axle hubs are environmentally friendly, as they can be easily recycled.

Application of Axle Hub in Various Industries

Axle hub finds its application in various industries, such as the Automotive Industry, Heavy Machinery, Transportation, Rail Industry, and Marine Applications. In the Automotive industry, axle hubs are used in passenger cars, trucks, and buses. In Heavy Machinery, axle hubs are used in construction equipment, cranes, and forklifts. In the Rail Industry, axle hubs are used in locomotives, passenger cars, and freight cars. In Marine Applications, axle hubs are used in boats, ships, and other marine vessels.

Future Development Trends and Opportunities of Axle Hub Products

The future of Axle hub products is bright, driven by the growing demand for fuel-efficient and environmentally friendly vehicles. The increasing demand for electric vehicles and the need for lightweight materials in the automotive industry are expected to drive the demand for aluminum axle hubs. The development of high-strength materials and advanced manufacturing techniques is expected to drive the growth of cast iron and steel axle hubs.

How to Choose a Suitable Axle Hub

Choosing a suitable axle hub is crucial for ensuring the smooth functioning of the vehicle. Several factors need to be considered while selecting an axle hub, such as Load Capacity, Size and Specifications, Material, Bearing Type, Operating Environment, and Installation Method. The load capacity of the axle hub should be sufficient to support the weight of the vehicle. The size and specifications of the axle hub should be compatible with the vehicle’s wheel assembly. The material of the axle hub should be selected based on the intended use and environmental conditions. The bearing type should be selected based on the load capacity and operating environment. The installation method should be compatible with the vehicle’s axle shaft.

Summary

In summary, axle hub is an essential component of the wheel assembly of a vehicle and has several performance characteristics. There are two main types of axle hubs, front and rear, and they can be classified based on their material composition. Axle hubs find their application in various industries, such as the Automotive Industry, Heavy Machinery, Transportation, Rail Industry, and Marine Applications. The future of Axle hub products is bright, driven by the growing demand for fuel-efficient and environmentally friendly vehicles. Choosing a suitable axle hub is crucial for ensuring the smooth functioning of the vehicle.

Author: Dream

All the content of this page is from the Internet. The content is only as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.